Bearings for Steel Industry

steel industry bearings Global customers

In steel equipment industry, globalization is the main trend. To maintain competitiveness means to be open to all opportunities.

We can offer the most competitive solutions to our partners.

Below are some of our references all over the world.

Chinese customers

In China, our bearings have such a good reputation that many steel plants use our products to replace the expensive imported bearings.

Below are some Chinese steel plants as our references.

Application

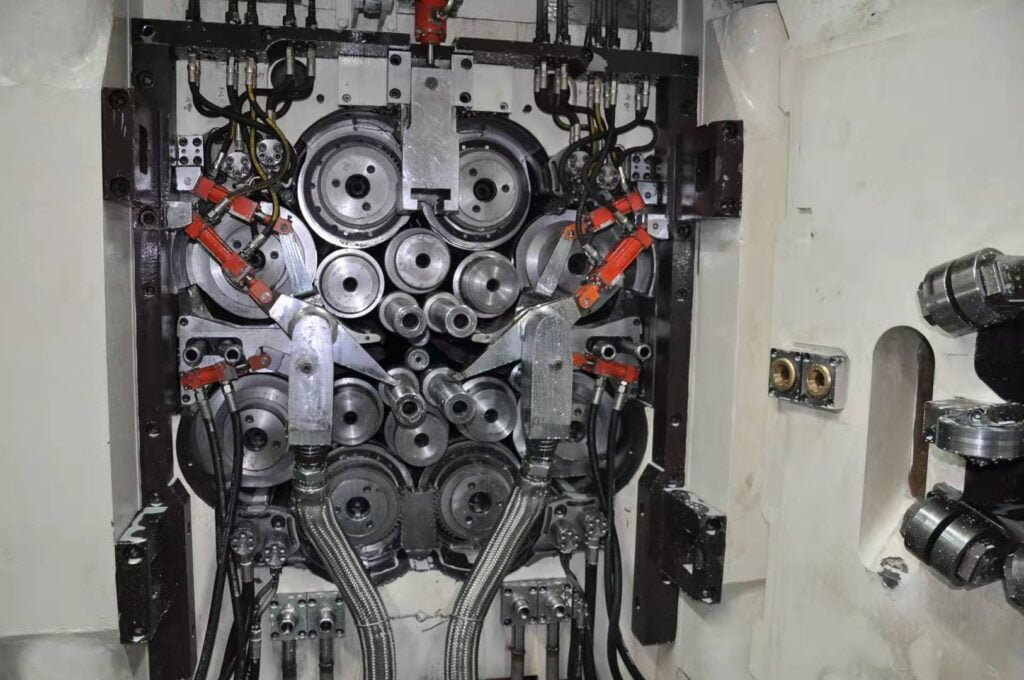

1. Multi-row Rolling Mill

Sendzimir backing bearings

Only a few bearing manufacturers has the technique and experience in manufacturing Sendzimir backing bearings.

We are the most cost-effective choice.

With many years of manufacturing and application experience, We are capable of supply P4, P2 precision class bearings for 20 high, 16 high, 12 high, 8 high rolling machines.

Our customers in China include many stainless steel factories and steel plants.

Our bearing service life is comparable to European and Japanese brands.

Neighboring H less than 0.002 mm

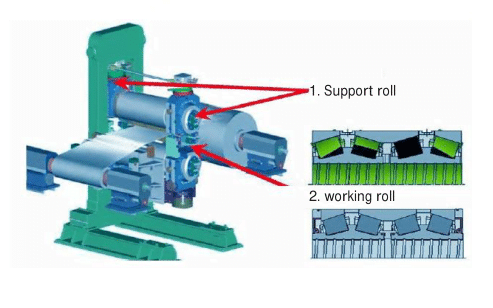

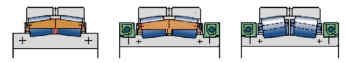

2. Rolling Mill Stand

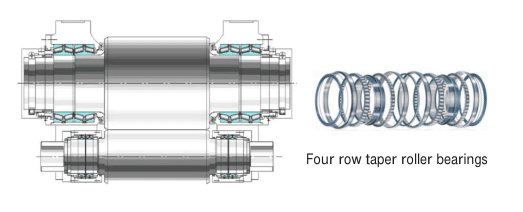

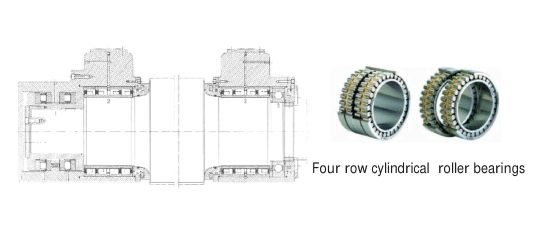

Four row cylindrical/taper roller bearings

Roll neck bearing and thrust bearings In hot rolling mill: for back-up roll, working roll, EVERGLORY can supply all kinds of multi-row roller bearings.

In cold rolling mills: for back-up roll, working roll, EVERGLORY can supply all kinds of multi-row roller bearings with high Precision class: P6, P5, P4.

There are also double row taper roller bearings used in cold rolling mills, with TDO, TDI configurations.

EVERGLORY supply full range of cold rolling and hot rolling bearings to most of the major steel plants in China.

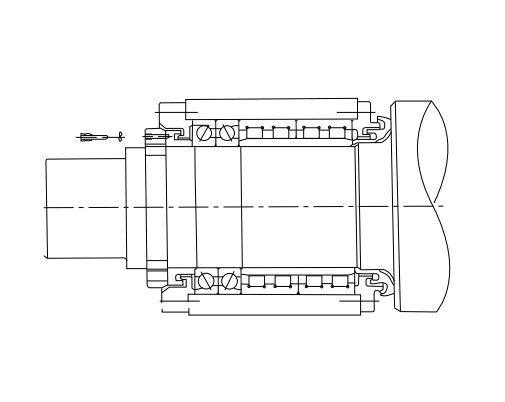

3. Converter Trunnion

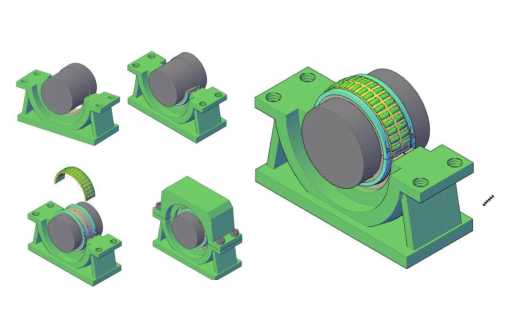

Split Spherical Roller Bearings

In steel converter, there is a fixed end and a floating end.

A tilting mechanism is on the floating side.

On the fixed side, there is a normal spherical roller bearing;

On the floating side, there is a split spherical roller bearing.

It can save up to 5 to 7 days maintenance time.

We supply this kind of bearing to many steel

factories in China.

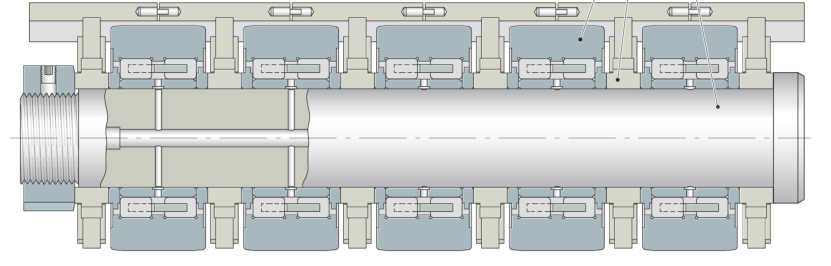

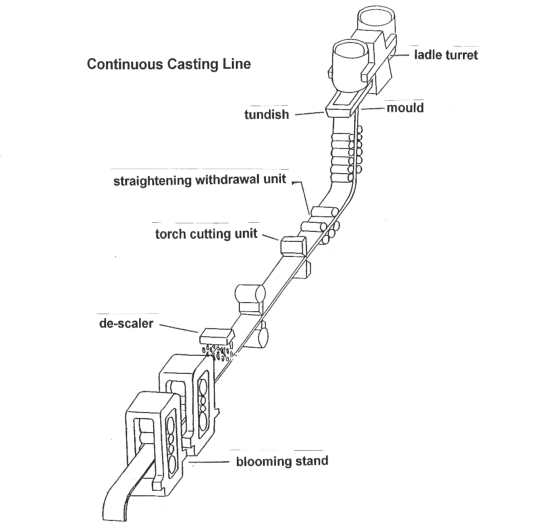

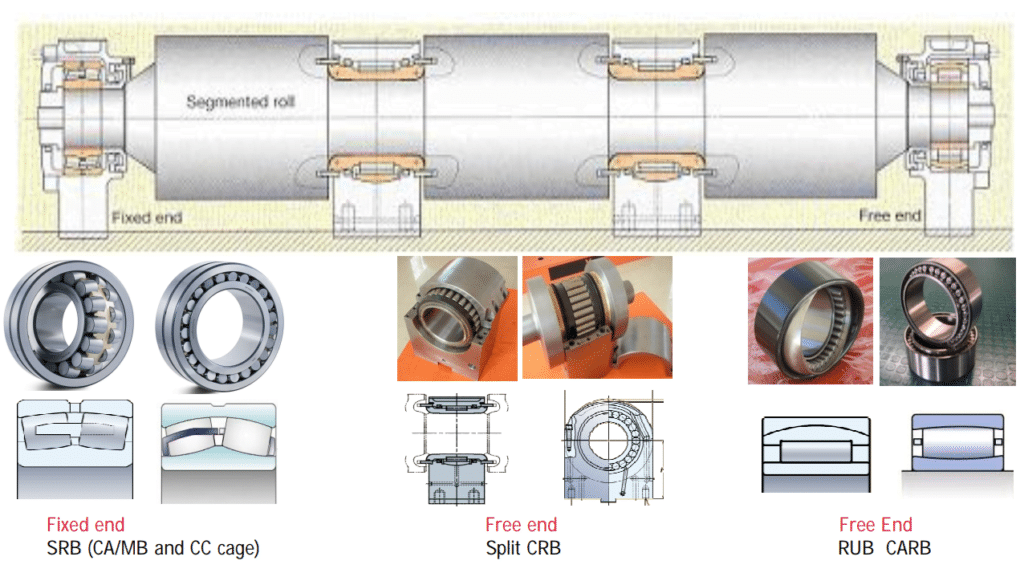

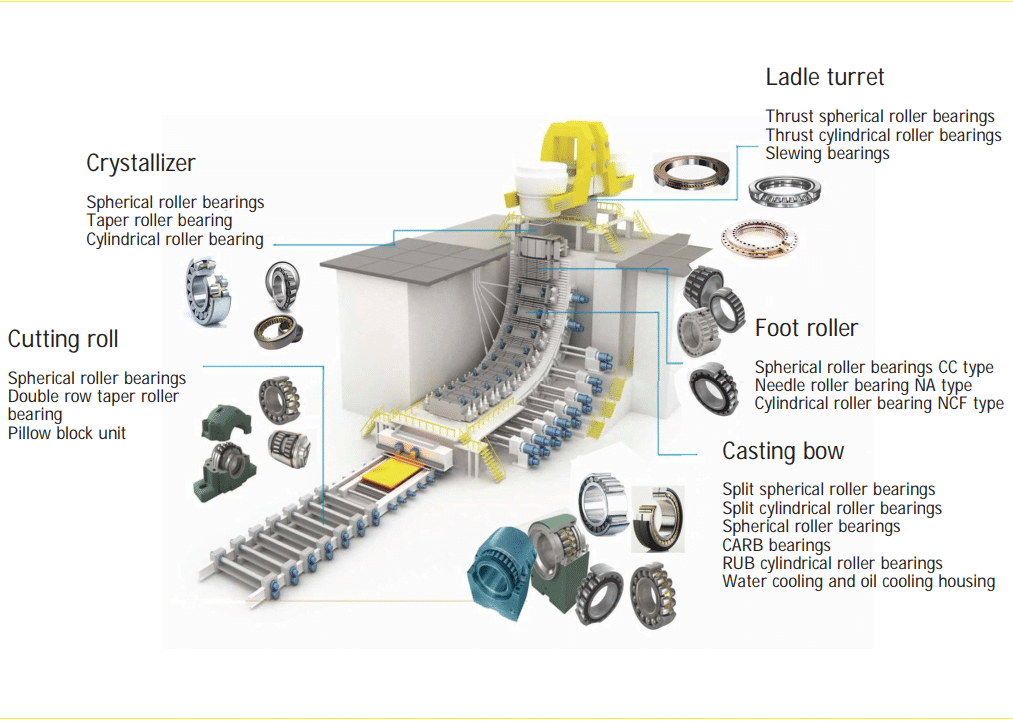

3. Continuous Caster

CARB bearings, RUB cylindrical roller bearings

For all kinds of continuous casting machine (CCM), EVERGLORY has developed full range of bearings:

- Fixed end: SRB (spherical roller bearing), sealed type.

- Middle: split bearing, internal cooling RUB type.

- Floating end: CARB bearings.

EVERGLORY can provide solution for all CCM bearings. bearings combination cylindrical.

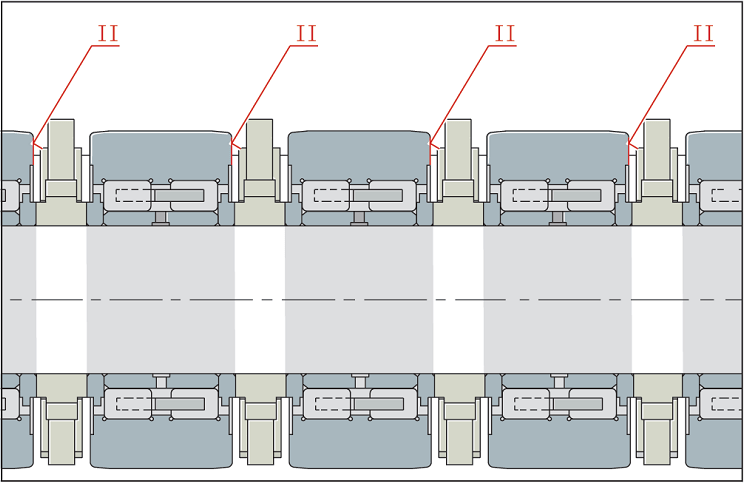

4. Continuous Caster

Continuous caster bearings

In continuous caster, EVERGLORY can provide full solution for all bearings.

Characteristics of continuous caster roll bearings

Working conditions:

heavy load, low speed, high temperature, wet, steam, highly contaminated with hammer scales.

Requirement for bearings:

- Heat resistant,

- Accommodating axial displacement.

- Self-aligning

- Resistant to shock load.

- Wear resistant, higher service life than roll.

- Good sealing and lubricating properties.

Clearance choosing:

Narrow slab caster: C3 clearance

Wide slab caster: C4 clearance

Split bearing clearance should be the same with other bearings.

- Design: material selection according to working environment.

- Manufacturing: CNC machining to ensure precision.

- Assembly: assemble and test before delivery, to check self aligning, center height

- Testing: specially designed testing equipment, to test sealing performance.

Test condition: cooling water circulation, heat resistant, under 38 Bar pressure

without leakage of water and lubricant within 10-15 minutes.

Quality Control

Total Quality Management is what we have adopted to improve our quality.

Advanced equipment ensures precision.

Strict workflow rules out possibility of flaw products.

Production

Precision class: P6 to P2 (¢100mm≤D≤¢1600mm)

Grinding: over 50 CNC grinding machines

Heat treatment: Bainite bath quenching.

you can also check EVERGLORY deep groove ball bearing information here !