What is Double Row Roller Cylindrical Bearing?

Double row cylindrical roller bearing is designed with large radial loads.

Double-row cylindrical roller bearings are well-suited for applications that involve significant radial loads. While standard versions (NN and NNU) are unable to handle axial forces, they are specifically designed for installation on shafts where compensating axial displacement is required. This is particularly useful in scenarios where thermal expansion of the shaft may occur.

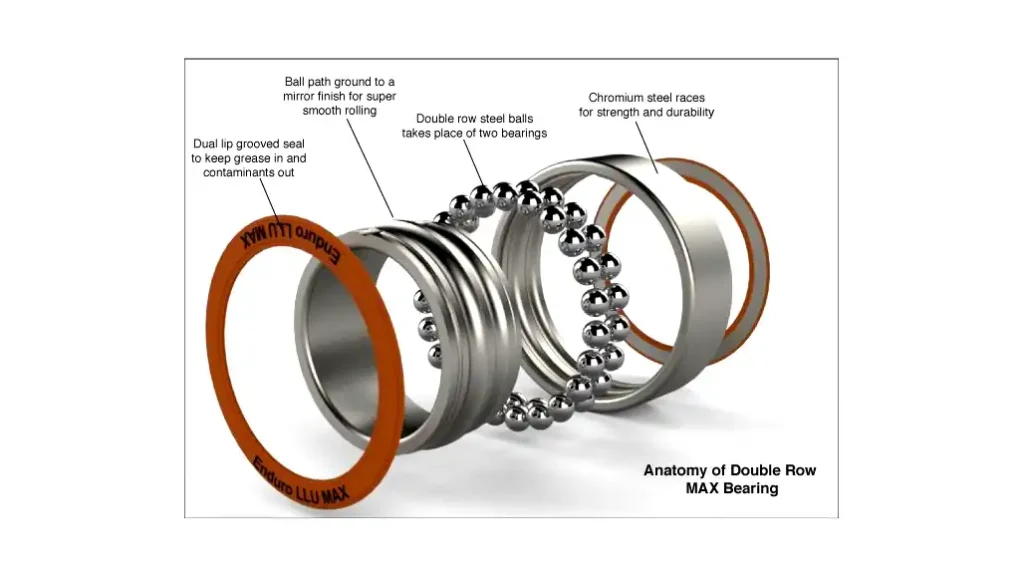

What Are the Components of a Cylindrical Roller Bearing?

A cylindrical roller bearing is a type of rolling element bearing that comprises four essential components, each playing a crucial role in its functionality. Here’s a detailed explanation of each component:

Inner Ring:

The inner ring, also known as the inner race or cone, is the part of the bearing that fits onto the rotating shaft. It serves as the primary load-carrying component and provides support to the rotating elements. The inner ring is typically mounted onto the shaft with a tight fit or through other secure attachment methods.

Outer Ring:

The outer ring, also referred to as the outer race or cup, is the stationary part of the bearing that houses the inner components. It provides support to the entire bearing structure and is often securely mounted within the surrounding machine or housing. The outer ring is designed to endure the external loads and forces acting on the bearing.

Rollers:

The rollers are cylindrical-shaped elements that are positioned between the inner and outer rings. These rolling elements facilitate the smooth rotation of the bearing and carry the radial and axial loads applied to the bearing. The design of the rollers allows them to distribute the load evenly, reducing friction and wear while enabling efficient rotation.

Cage:

A cylindrical roller bearing consists of an inner ring (inner race), an outer ring (outer race), cylindrical rollers, and a cage (retainer). Together, these components work in harmony to enable the bearing to support and facilitate the smooth rotation of shafts in a variety of applications, ranging from automotive and industrial machinery to other mechanical systems.

What Are Double Roller Bearings Used For?

Double Row or Two Row cylindrical roller bearings are a type of rolling element bearing specifically designed to handle heavy loads that cannot be effectively managed by a single row bearing.

The key feature that distinguishes them from single row bearings is the presence of two parallel rows of cylindrical rollers.

The primary advantage of having two rows of rollers is that it enhances the bearing’s ability to support increased radial loads. Radial loads refer to forces that act perpendicular to the axis of rotation, and these bearings are constructed to withstand higher amounts of such loads due to the additional row of rollers.

The arrangement of the two rows allows for a greater contact area between the rollers and the inner and outer raceways of the bearing. This increased contact area helps distribute the load more evenly, reducing stress on individual rollers and enhancing the overall load-carrying capacity of the bearing.

In applications where heavy axial and radial loads are present, such as in industrial machinery, automotive systems, or large-scale equipment, double row cylindrical roller bearings are chosen for their durability and ability to handle challenging conditions. Their design is particularly suitable for situations where a single row bearing might be insufficient, making them a reliable choice for demanding mechanical setups.

Where Are Double Row Roller Bearing Used?

Double row tapered roller bearings are commonly used in various industrial applications due to their specific design and capabilities. Here is a list of typical uses for double row tapered roller bearings:

Gearboxes:

Double row tapered roller bearings are often employed in gearboxes where they efficiently handle both radial and axial loads. Their design enables them to withstand the rigors of gear transmission systems.

Hoisting Equipment:

Hoisting equipment, such as cranes and elevators, requires bearings that can support heavy loads and provide reliable performance. Double row tapered roller bearings are chosen for their capacity to handle the vertical and horizontal forces involved in hoisting applications.

Rolling Mills:

In rolling mills, where metal is processed into sheets or other forms, double row tapered roller bearings play a crucial role. They contribute to the smooth rotation of rollers, ensuring precision and durability in the metalworking process.

Mining Industry Machines:

Machines used in the mining industry often operate in harsh conditions with heavy loads and vibrations. Double row tapered roller bearings are preferred in mining equipment, including crushers, conveyors, and excavators, where they provide robust performance and reliability.

Railway Applications:

Double row tapered roller bearings are utilized in railway applications, particularly in wheelsets and axle boxes. Their ability to handle both radial and axial loads makes them suitable for the dynamic conditions encountered in rail transport.

Construction Equipment:

Various construction machines, such as excavators, bulldozers, and loaders, rely on double row tapered roller bearings for their durability and load-bearing capabilities. These bearings contribute to the efficient functioning of moving parts in construction equipment.

Automotive Industry:

Certain automotive applications, especially in heavy-duty vehicles and trucks, use double row tapered roller bearings. These bearings can endure the high loads and harsh conditions often encountered in automotive drivetrains.

Agricultural Machinery:

Agricultural equipment, including tractors and combines, may incorporate double row tapered roller bearings. The bearings provide the necessary support for components exposed to heavy loads and dynamic forces in the field.

In summary, double row tapered roller bearings find widespread application in gearboxes, hoisting equipment, rolling mills, machines in the mining industry, railway applications, construction equipment, automotive industry, and agricultural machinery due to their robust design and ability to handle diverse operational challenges.

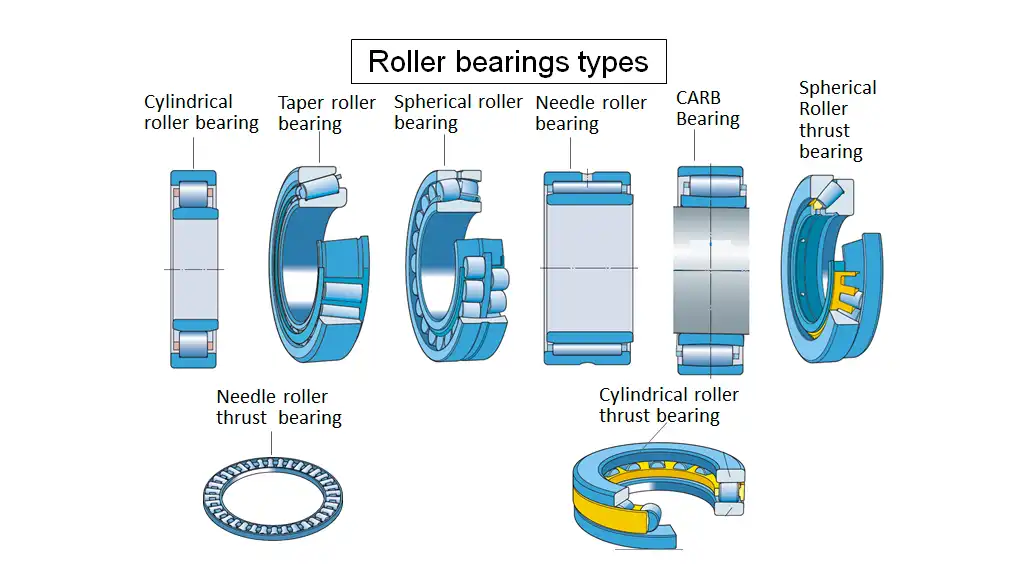

What Are the Two Types of Roller Bearings?

Roller bearings are mechanical components widely used in various applications to facilitate smooth rotation and reduce friction between moving parts.

There are three principal types of roller bearings: cylindrical, spherical, and tapered.

Cylindrical Roller Bearings:

- Design: These bearings consist of cylindrical rollers arranged parallel to the axis of rotation.

- Applications: Commonly used in applications with high radial loads, such as in electric motors and machine tools.

- Advantages: Provide high radial load capacity and good rigidity.

Spherical Roller Bearings:

- Design: Spherical roller bearings have barrel-shaped rollers that align themselves with the concave outer raceway.

- Applications: Suitable for applications with heavy axial loads and misalignment, often used in mining, construction, and industrial gearboxes.

- Advantages: Can accommodate misalignment and high axial loads.

Tapered Roller Bearings:

- Design: Tapered rollers are arranged in a conical shape, with the large end on the outer ring and the small end on the inner ring.

- Applications: Commonly used in automotive applications, such as wheel bearings, as well as in gearboxes and heavy machinery.

- Advantages: Can handle both radial and axial loads, providing high thrust capacity.

Now, let’s create a simple table summarizing the key features of each type:

| Bearing Type | Design | Applications | Advantages |

|---|---|---|---|

| Cylindrical Roller Bearings | Cylindrical rollers parallel to axis | High radial loads (e.g., electric motors) | High radial load capacity, good rigidity |

| Spherical Roller Bearings | Barrel-shaped rollers, align with outer raceway | Heavy axial loads, misalignment (e.g., mining) | Accommodates misalignment, high axial load capacity |

| Tapered Roller Bearings | Conical rollers, large end on outer ring | Automotive, gearboxes, heavy machinery | Handles radial and axial loads, high thrust capacity |

This table provides a quick overview of the design, applications, and advantages of each principal type of roller bearing.

Why Use Cylindrical Roller Bearings?

Cylindrical roller bearings are widely used in various applications due to their specific design features, which make them highly suitable for certain operating conditions. Here are some key reasons why cylindrical roller bearings are preferred and the benefits they offer:

Resistance to Damage from Fatigue:

Cylindrical roller bearings are designed to withstand repeated cycles of loading and unloading without suffering fatigue failure. This fatigue resistance is crucial in applications where the bearing is subjected to continuous or fluctuating loads over time, ensuring a longer operational life.

Shock and Edge Load Resistance:

These bearings are particularly robust and can handle shock loads and edge loads effectively. In situations where sudden impacts or varying loads are common, cylindrical roller bearings provide stability and durability, reducing the risk of premature failure.

Tolerance to Misalignment:

Cylindrical roller bearings exhibit good tolerance to misalignment. This means they can accommodate slight shaft misalignments without significantly compromising their performance. This feature is beneficial in real-world applications where perfect alignment may be challenging to achieve.

Lower Maintenance Costs:

Due to their durability and resistance to various types of loads, cylindrical roller bearings often require less frequent maintenance. The reduced need for repairs or replacements contributes to lower overall maintenance costs for machinery and equipment.

Extended Equipment Life:

The ability of cylindrical roller bearings to resist fatigue, shock, and misalignment directly contributes to an extended equipment life. By withstanding harsh operating conditions, these bearings help maximize the longevity of the entire system, providing a reliable and cost-effective solution for end-users.

Cost Savings for Customers:

Ultimately, the combination of lower maintenance costs and extended equipment life translates into cost savings for customers. Businesses benefit from reduced downtime, fewer replacement parts, and a more reliable operational process, leading to improved efficiency and a positive impact on the bottom line.

Conclusion

A double row roller cylindrical bearing is a type of bearing that consists of two rows of cylindrical rollers arranged in parallel, providing increased load capacity and improved radial stiffness.

For more detailed information about double row roller cylindrical bearings, please feel free to contact us at any time.