In the intricate world of machinery, selecting the right components is paramount. This article delves into the extensive applications of cylindrical roller bearings, showcasing their versatility and impact on various industries. From enhancing load capacity to ensuring smooth operations, discover the key aspects that make cylindrical roller bearings indispensable.

What Is Cylindrical Roller Bearing

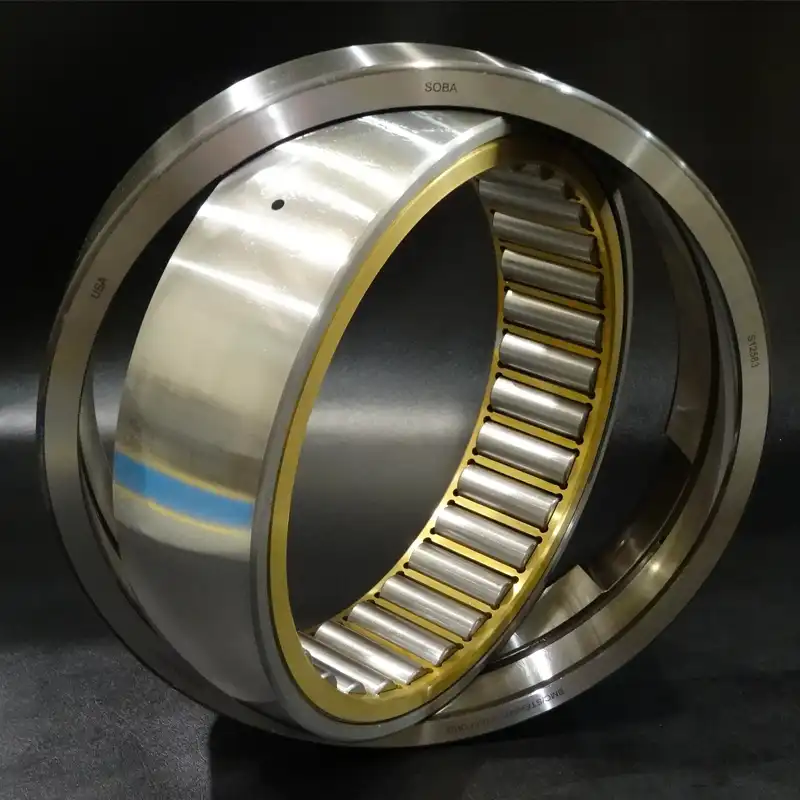

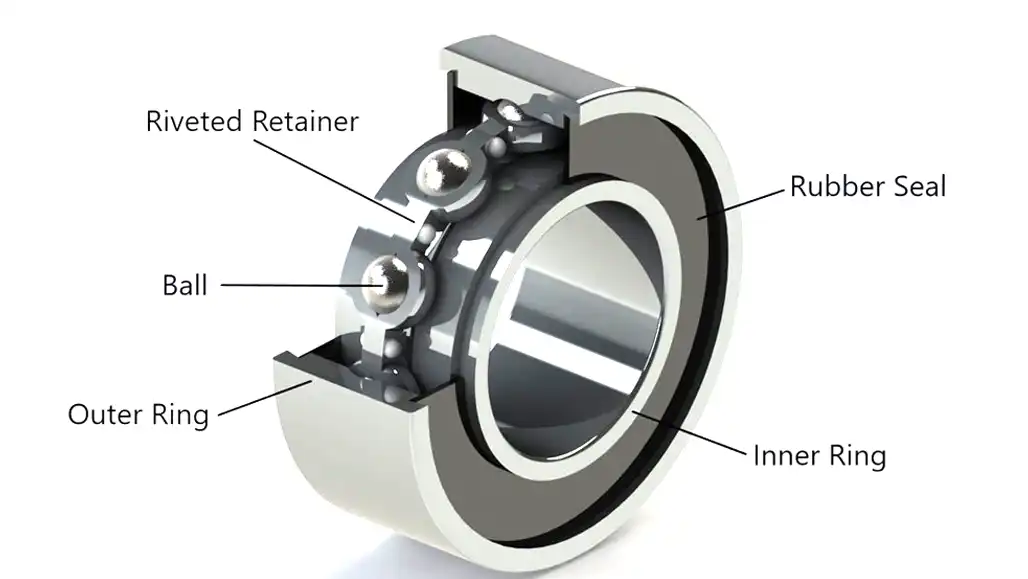

The cylindrical roller bearing is a crucial component in machinery, facilitating smooth rotational motion. It features cylindrical rollers that distribute the load evenly across their length, allowing for high radial load capacity. This design ensures efficiency in various applications, from precision machinery to heavy-duty industries.

These bearings stand out for their ability to handle substantial radial loads, making them essential for equipment subjected to significant stress. Their reduced friction contributes to energy efficiency and smoother operations, enhancing overall machinery performance.

Cylindrical roller bearings find applications across diverse sectors, including automotive, aerospace, heavy machinery, renewable energy systems, medical equipment, robotics, and textile machinery. Their adaptability, reliability, and ease of installation make them a preferred choice in industries where precision and efficiency are paramount.

Cylindrical Roller Bearings Applications

Cylindrical roller bearings, with their versatile design, find applications in various mechanical systems, catering to distinct needs and requirements. Understanding the different types of cylindrical roller bearings unveils a spectrum of uses, each contributing to the seamless operation of machinery.

Here are some popular working conditions that cylindrical roller bearings used for in the following:

Axial Displacement

Among the myriad applications, cylindrical roller bearings excel in supporting axial loads and facilitating movement in axial directions within machinery. Specifically, the N and NU types of cylindrical roller bearings are tailored for axial displacement, offering a reliable scope within specified limits relative to the housing. This feature enhances the flexibility and efficiency of mechanical systems, ensuring optimal performance in scenarios where axial movement is critical.

Withstand Incidental Thrust Loads

The NF, NJ, and NUP series of cylindrical roller bearings are meticulously designed to withstand incidental thrust loads, in addition to radial loads. Thrust loads, applied parallel to the rotation axis, pose a unique challenge, and these bearings efficiently address such demands. This capability makes them essential components in machinery where both radial and thrust loads are prevalent, ensuring durability and stability in operation.

Heavy Machinery and Extreme Systems

Cylindrical roller bearings shine in high-speed systems and find crucial roles in heavy machinery and extreme environments. Industries such as agriculture, wind energy, and mining rely on these bearings for their ability to endure demanding conditions while delivering high performance. The robustness of cylindrical roller bearings makes them a preferred choice in systems where reliability is paramount.

Versatility Across Industries

Beyond the previously mentioned applications, cylindrical roller bearings exhibit versatility across a myriad of industries. In the oil and gas sector, they contribute to the smooth operation of drilling equipment. Gearboxes rely on these bearings for efficient power transmission. Wind turbines harness their capabilities to endure dynamic conditions.

In machine tools, electric motors, material handling equipment, pumps, and steel mills, cylindrical roller bearings stand as indispensable components, ensuring reliable and efficient machinery operation.

What Are Cylindrical Roller Bearings Used For?

Cylindrical roller bearings, with their superior radial load capacity, ability to accommodate higher speeds, and various other advantages, are indispensable in diverse industries. These essential components find applications in:

- Oil and gas sectors

- Gearboxes

- Wind turbines

- Machine tools

- Electric motors

- Material handling equipment

- Pumps

- Steel mills

Their widespread use across these markets showcases the adaptability and reliability of cylindrical roller bearings, making them integral to the efficient functioning of machinery in numerous industries.

Supply of Multi-Row Cylindrical Roller Bearings for Industrial Use

Often overlooked due to their small size, multi-row cylindrical roller bearings can make a massive difference in the performance of machinery. But what exactly are they?

Multi-row cylindrical Roller Bearings are a type of rolling-element bearing that utilize cylinders to maintain the separation between moving parts. They have multiple rows of rolling elements (cylindrical rollers), which maximizes load-carrying capacity. The uniqueness of MRCRB allows them to handle heavy radial loads, while still achieving high-speed operation.

- Radial Load Bearing: MRCRB primarily handles radial loads, which act perpendicular to the shaft’s axis.

- High Load Carrying Capacity: These bearings offer exceptional load-carrying capacity owing to multiple rows of rolling elements.

- High-speed Operation: MRCRB can tolerate high-speed rotation, essential in many industrial applications.

The Industrial Significance of Multi-Row Cylindrical Roller Bearings

MRCRB holds a significant position in myriad industrial applications, ranging from wind turbines to railway axle boxes. They contribute to elevating performance and reducing maintenance downtime, which culminates in improved productivity.

Role in Industries

These bearings are integral components in several heavy industries, such as transportation, manufacturing, and energy sectors. Their robust nature and ability to endure high radial loads make them an ideal choice for heavy-duty machinery and equipment.

Maintaining an Adequate Supply of MRCRB

With MRCRB being such critical elements in sustaining industrial operations, it is paramount for enterprises to maintain a consistent and reliable supply chain.

Gauging the Demand

Understanding your industry’s needs is the first step in maintaining an adequate supply of these bearings. This involves assessing the frequency of replacement, the type of bearings most commonly used, and the implications of downtime due to bearing failure.

Supplier Selection

Choosing a reliable supplier is essential. The quality of bearings can significantly affect the maintenance frequency and overall performance of your machinery. Check their track record, quality of bearings, availability, and support services.

FAQs

How do cylindrical roller bearings differ from other types?

Can cylindrical roller bearings handle axial loads?

Are cylindrical roller bearings suitable for high-speed applications?

What maintenance is required for cylindrical roller bearings?

Can cylindrical roller bearings be replaced individually, or is it recommended to replace them as a set?

Are there environmental considerations for cylindrical roller bearings?

Conclusion

In conclusion, the cylindrical roller bearing application spans across diverse industries, contributing to enhanced efficiency and reliability. Understanding their advantages and optimal use in specific sectors empowers industries to make informed decisions, ensuring seamless operations and prolonged machinery lifespan.