Cylindrical roller bearings (CRBs) feature a straightforward design with cylindrical rollers in direct contact with the raceways, providing substantial load capacity, especially under radial loads. The low friction between the rollers and ring ribs makes these bearings well-suited for high-speed rotations.

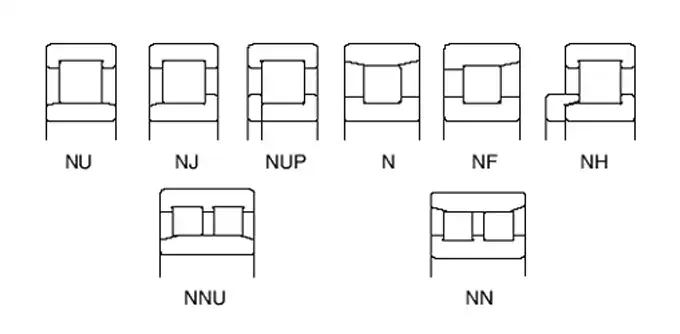

Single-row bearings carry designations such as NU, NJ, NUP, N, or NF, while double-row bearings are labeled as NNU or NN, depending on the presence of side ribs. In all types, the inner and outer rings can be separated.

In instances where CRBs function as free-end bearings without ribs, allowing axial movement between rings, they are employed. Bearings with ribs on one side of the inner or outer ring and ribs on both sides of the other can accommodate axial loads in one direction.

Double-row cylindrical roller bearings exhibit high radial rigidity and find application primarily in the main shafts of precision machine tools. Cages are typically constructed from pressed steel or machined brass, although some models utilize molded polyamide resin cages.

We can provide a diverse range of CRB types to meet various requirements.

Explore our comprehensive selection of high-quality cylindrical roller bearings designed to meet the demands of diverse industrial applications. Cylindrical roller bearings, known for their exceptional load-carrying capacity and robust design, play a crucial role in ensuring smooth and efficient machinery operation.

Here are many different types of cylindrical roller bearings in the bearing industry, and we can show some trending types here for your selection.

NU, N, NNU, NN: Appropriate for use as bearings with unrestricted movement.

NJ, NF: Capable of withstanding limited axial loads in a singular direction.

NH, NUP: Suitable for application as stationary-end bearings. NH variants consist of a NJ-type cylindrical roller bearing paired with an HJ-type L-shaped thrust collar.

An Axial Cylindrical Roller Bearing is a type of cylindrical roller bearing specifically designed to handle axial (thrust) loads along the rotational axis.

Two-row or double row cylindrical roller bearings have high radial rigidity and are used primarily for precision machine tools. They provide a high load-carrying capacity and are suitable for heavy radial loads.

Double row full complement cylindrical roller bearing can withstand large radial and axial loads in addition to overturning moments, and are therefore long used as stationary bearings.

NU type and N type allow shaft moving in axial direction within limits, applicable to use as free end.

NJ type and NF type can carry certain extent one-way axial load.

NUP type and NH type can carry certain extent both-way axial load.

single row cylindrical roller bearings (oil field dedicated)

The oil field industry is a critical sector of the economy, and bearings play a vital role in its operations. Bearings are used in a wide range of applications in the oil field, from drill bits and pumps to valves and compressors.

Full complement cylindrical roller bearings are designed to carry heavy loads. With the same width, these bearings have a very high load carrying capacity and a small radial cross section compared to conventional type bearings with cages, allowing for space saving but relatively low speeds.

In order for the bearings to work properly, they must be subjected to a certain minimum load in continuous operation, i.e. C/P < 25. Otherwise, wear will increase due to insufficient lubrication and high speeds.

A cylindrical roller bearing is a type of rolling-element bearing that utilizes cylindrical rollers to support radial loads. These rollers are in contact with the inner and outer raceways, providing efficient load distribution.

Ball bearings and roller bearings differ primarily in the shape of the rolling elements they use. Ball bearings employ spherical balls to facilitate smooth rotation between the inner and outer raceways, while roller bearings, on the other hand, utilize cylindrical or tapered rollers for the same purpose. This distinction in design affects factors such as load capacity, friction, and suitability for various applications. Generally, ball bearings are advantageous in high-speed, light-load scenarios, whereas roller bearings excel in heavier radial load conditions due to their larger contact surface area.

Cylindrical roller bearings differ from ball bearings and tapered roller bearings in that they use cylindrical rollers instead of balls or tapered rollers. They are designed to handle higher radial loads and offer better rigidity.

The main components include an inner ring, an outer ring, cylindrical rollers, and a cage that holds the rollers in place. The inner and outer rings contain the raceways where the rollers move.

Cylindrical roller bearings offer high radial load capacity, good rigidity, and are suitable for high-speed applications. They can accommodate misalignment and axial loads to some extent.

Here is a list of advantages of cylindrical roller bearings, including the provided points:

High Reliability for Diverse Applications:

Cylindrical roller bearings are designed to offer high reliability, making them suitable for a wide range of applications.

Environmentally Friendly with Reduced Resource Consumption:

They contribute to environmental sustainability by ensuring less resource consumption in their operation and maintenance.

Greater Radial Load Bearing Capacity:

Cylindrical roller bearings exhibit a higher radial load bearing capacity compared to other ball bearings of the same size, making them suitable for applications with heavier loads.

Linear Contact with Raceways for Faster Speed:

The linear contact with raceways enables faster speeds, enhancing overall productivity in various industrial settings.

Minimal Maintenance Requirements:

Cylindrical roller bearings are known for their minimal maintenance needs, reducing the risk of damage caused by overuse and ensuring prolonged operational life.

Resistance to Damage from Overuse:

Their design minimizes the likelihood of damage from overuse, contributing to their durability and reliability in demanding operating conditions.

Additional Rows for Supporting Heavier Radial Loads:

The availability of additional rows in the design allows cylindrical roller bearings to effectively support heavier radial loads, providing robust performance in challenging applications.

Cylindrical roller bearings thus offer a combination of durability, load-bearing capacity, and efficiency, making them a preferred choice in various industries.

They are widely used in various industries, including automotive, machinery, and power generation. Common applications include gearboxes, electric motors, pumps, and machine tool spindles.

Yes, cylindrical roller bearings are available with seals. Sealed cylindrical roller bearings are designed to prevent the ingress of contaminants such as dust and moisture, enhancing the bearing’s performance and extending its lifespan. These seals help maintain proper lubrication inside the bearing, reduce the risk of damage due to external elements, and contribute to overall reliability in various industrial applications. When selecting cylindrical roller bearings with seals, it’s essential to consider specific sealing configurations and the intended operating conditions to ensure optimal performance and protection.

Choosing a cylindrical roller bearing over a radial ball bearing depends on the specific application requirements and the loads the bearing will encounter. Here are some reasons one might prefer a cylindrical roller bearing:

Higher Radial Load Capacity: Cylindrical roller bearings are designed to handle higher radial loads compared to radial ball bearings. They are well-suited for applications with heavier radial loads.

Improved Rigidity: Cylindrical roller bearings provide better rigidity due to their design with cylindrical rollers. This feature makes them suitable for applications where deflection or misalignment needs to be minimized.

Enhanced Axial Load Capacity: While primarily designed for radial loads, cylindrical roller bearings can also accommodate some axial loads. This makes them versatile in applications where both radial and axial loads may be present.

Suitability for High-Speed Applications: Cylindrical roller bearings are often preferred in high-speed applications, as they can handle higher speeds with reduced heat generation compared to radial ball bearings.

Variety of Configurations: Cylindrical roller bearings come in various configurations, including single-row, double-row, and full-complement designs. This allows for greater flexibility in meeting specific application needs.

Adaptability to Misalignment: Cylindrical roller bearings can accommodate certain degrees of misalignment, making them suitable for applications where shaft deflection or misalignment is a concern.

It’s essential to carefully consider the load requirements, operating conditions, and specific features needed for a particular application when choosing between cylindrical roller bearings and radial ball bearings. Each type has its advantages, and the selection should align with the demands of the machinery or system in which the bearing will be used.

EGI bearing manufacturer could your first choice, if you are looking for a reliable bearing manufacturing from China. Send us your requirement to get an instant quote now.