Unlike traditional bearings, which consist of a solid, one-piece construction, split bearings are divided into two or more components, allowing for convenient access to the bearing assembly without the need to disassemble surrounding equipment.

Differing from the traditional bearings, consisting a solid, one-piece structure, the split bearing is divided into two or more components. It is much more convenient for you to access to the bearing assembly without needing to disassemble surrounding equipment.

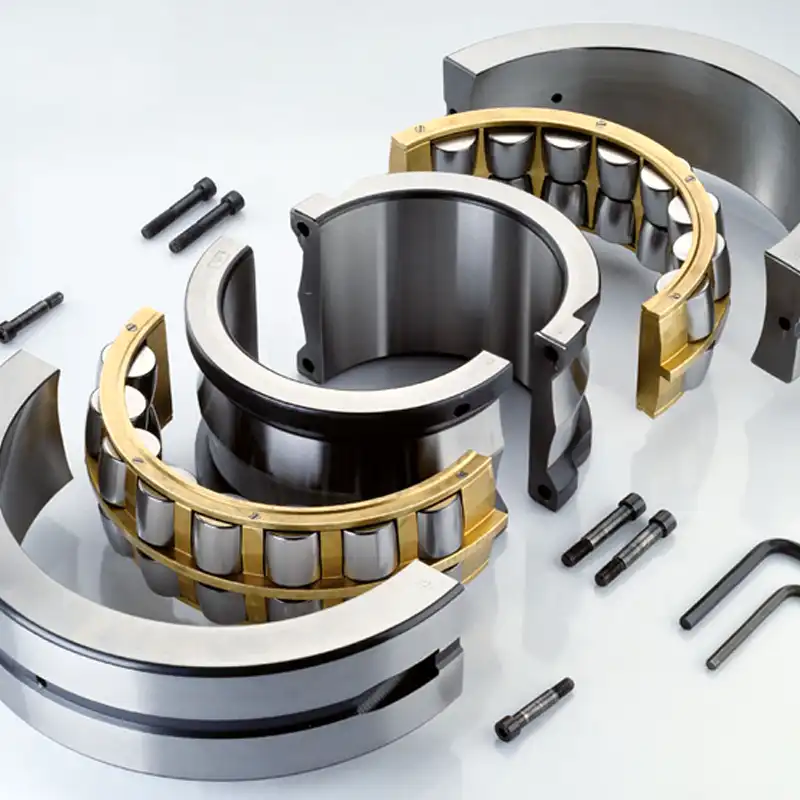

Split bearings, also known as split roller bearings or split ball bearings, are a type of bearing designed to facilitate easier installation, maintenance, and replacement in industrial machinery.

Introduction to Split Bearings

Split bearings play a crucial role in various industries where rotating machinery is prevalent. These bearings are engineered to withstand heavy loads, high speeds, and harsh operating conditions, making them indispensable components in applications ranging from manufacturing plants to transportation vehicles.

Types of Split Bearings

There are several types of split bearings available, including plain split bearings, split roller bearings, and split ball bearings. Each type has its unique design and advantages, catering to specific application requirements.

Advantages of Split Bearings

One of the primary advantages of split bearings is their ease of installation. By eliminating the need to disassemble adjacent components, downtime during maintenance or replacement procedures is significantly reduced. Additionally, split bearings offer accessibility for inspection and lubrication, contributing to extended equipment lifespan and improved operational efficiency.

Applications of Split Bearings

Split bearings find widespread use in various industries, including manufacturing, mining, construction, and transportation. They are commonly employed in machinery such as conveyors, pumps, fans, and gearboxes, where reliable performance and minimal downtime are essential.

How Split Bearings Work

Split bearings consist of two main components: the inner ring assembly and the outer ring assembly. These components are securely fastened together using bolts or clamps, forming a complete bearing unit. Inside the bearing, rolling elements such as balls or rollers facilitate smooth rotation between the inner and outer rings.

Factors to Consider When Choosing Split Bearings

When selecting split bearings for a particular application, several factors must be taken into account, including load capacity, speed capability, and environmental conditions. It is essential to choose a bearing that can withstand the operating conditions and provide reliable performance over its intended lifespan.

Installation Process of Split Bearings

The installation of split bearings follows a systematic procedure to ensure proper alignment and functionality. This process typically involves preparing the mounting surfaces, aligning the bearing halves, and tightening the fasteners to the specified torque values.

Maintenance and Care for Split Bearings

Regular maintenance is crucial for maximizing the lifespan of split bearings and preventing premature failure. This includes periodic inspections, proper lubrication, and timely replacement of worn or damaged components. By adhering to a proactive maintenance schedule, the risk of unexpected downtime can be minimized.

Comparison with Traditional Bearings

In comparison to traditional solid bearings, split bearings offer several distinct advantages, including easier installation, accessibility for maintenance, and cost-effectiveness. While traditional bearings remain suitable for certain applications, split bearings are increasingly favored in industries where rapid maintenance turnaround and extended service intervals are paramount.

Environmental Impact of Split Bearings

Split bearings contribute to environmental sustainability by reducing waste and energy consumption associated with maintenance activities. Additionally, the materials used in split bearing construction are often recyclable, further minimizing their environmental footprint. By choosing split bearings over traditional alternatives, businesses can demonstrate their commitment to sustainability and responsible resource management.

Expert Tips for Maximizing Split Bearing Lifespan

To maximize the lifespan of split bearings, it is essential to follow proper handling and storage procedures. This includes protecting bearings from contamination, ensuring they are stored in a clean and dry environment, and avoiding mishandling during installation and maintenance activities.

Conclusion

In conclusion, split bearings offer numerous advantages over traditional solid bearings, making them an ideal choice for applications where ease of installation, maintenance accessibility, and cost-effectiveness are priorities. By understanding the benefits and considerations associated with split bearings, businesses can optimize their equipment performance and minimize downtime, ultimately enhancing operational efficiency and profitability.

FAQs about Split Bearings

- What are the main advantages of split bearings?

- Split bearings offer easier installation, accessibility for maintenance, and cost-effectiveness compared to traditional solid bearings.

- In which industries are split bearings commonly used?

- Split bearings find widespread use in industries such as manufacturing, mining, construction, and transportation.

- How do split bearings differ from traditional bearings?

- Split bearings are divided into two or more components, allowing for easier access during installation and maintenance, whereas traditional bearings are solid one-piece constructions.

- What factors should be considered when choosing split bearings?

- Factors such as load capacity, speed capability, and environmental conditions should be taken into account when selecting split bearings for a particular application.

- How can businesses maximize the lifespan of split bearings?

- Proper handling, regular maintenance, and adherence to manufacturer recommendations are essential for maximizing the lifespan of split bearings.