Welcome to the world of cylindrical roller bearings, where precision meets efficiency.

In this detailed guide, we will delve into the intricacies of what is cylindrical roller bearings, exploring its design, applications, and advantages. Whether you’re a seasoned engineer or a curious enthusiast, this article promises to demystify the cylindrical roller bearing.

What Is Cylindrical Roller Bearing?

Cylindrical Roller Bearing Definition

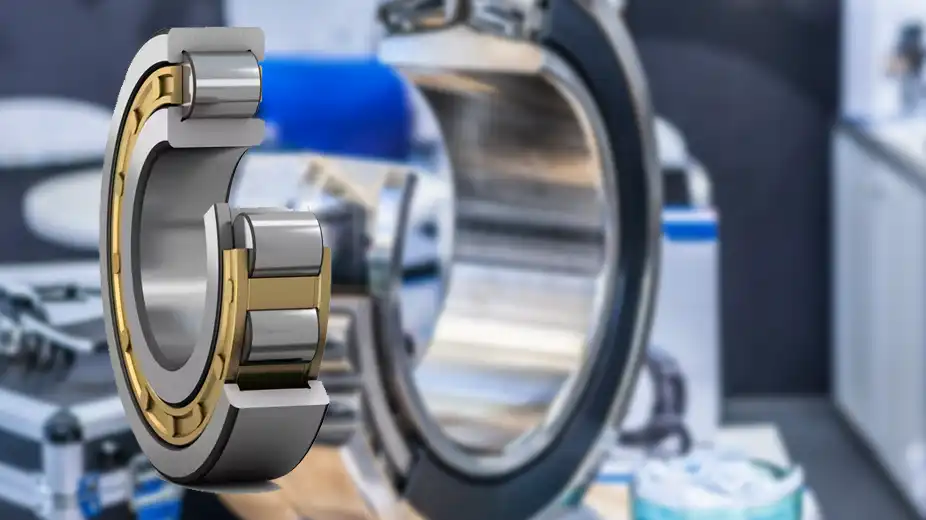

A cylindrical roller bearing is a type of rolling element bearing that facilitates rotation between two moving parts. It consists of cylindrical rollers held in place by an inner and outer race (or ring), with the rollers positioned parallel to the axis of the bearing. This design allows the cylindrical roller bearing to handle both radial and axial loads.

The cylindrical shape of the rollers distributes the load evenly over a larger surface area, enabling the bearing to support heavy radial loads. Additionally, the configuration allows for limited axial movement, making cylindrical roller bearings suitable for applications where axial space is limited.

Cylindrical roller bearings have wide applications and are commonly used in various machinery and equipment, such as automotive transmissions, conveyor systems, and industrial gearboxes, where they contribute to smooth and efficient rotation while withstanding significant loads.

Inner and Outer Rings

The inner and outer rings serve as the foundation of the cylindrical roller bearing. The inner ring is mounted on the shaft, while the outer ring is fixed in the housing. This configuration enables the bearing to support and guide the rotating shaft.

Rolling Elements: Cylindrical Rollers

Cylindrical rollers are the workhorses of the bearing. These cylindrical-shaped components distribute the load evenly across the bearing, minimizing friction and ensuring smooth operation. The design of the rollers allows them to accommodate both radial and axial loads.

Cage Design

The cage, positioned between the rollers, maintains proper spacing and alignment. It prevents the rollers from coming into contact with each other, reducing friction and wear. The cage design plays a pivotal role in extending the lifespan of the cylindrical roller bearing.

-

Split Cylindrical Roller Bearing

Split Cylindrical Roller Bearing -

Cylindrical Roller Thrust Bearing

Cylindrical Roller Thrust Bearing -

single row cylindrical roller bearing (oil field dedicated)

single row cylindrical roller bearing (oil field dedicated) -

Double Row Cylindrical Roller Bearing

Double Row Cylindrical Roller Bearing -

Four Row Cylindrical Roller Bearing

Four Row Cylindrical Roller Bearing -

Double Row Full Complement Cylindrical Roller Bearing

Double Row Full Complement Cylindrical Roller Bearing -

Single Row Full Complement Cylindrical Roller Bearing

Single Row Full Complement Cylindrical Roller Bearing -

Single Row Cylindrical Roller Bearing

Single Row Cylindrical Roller Bearing

What Are Cylindrical Roller Bearings Used For

Cylindrical roller bearings, with their robust design and versatile features, find extensive applications across various industries. Let’s explore the diverse uses of these essential components.

Automotive Industry

Wheel Hubs: Cylindrical roller bearings are integral to the functionality of wheel hubs in vehicles. They provide reliable support, ensuring smooth rotation and efficient load distribution.

Transmissions: In automotive transmissions, these bearings play a crucial role in supporting shafts and reducing friction, contributing to the overall efficiency of the transmission system.

Engines: Cylindrical roller bearings are utilized in engine components, such as crankshafts and camshafts. Their ability to handle radial loads makes them ideal for these dynamic applications.

Industrial Machinery

Conveyor Systems: Industrial conveyor systems rely on cylindrical roller bearings for seamless motion. These bearings facilitate the movement of conveyor belts, ensuring efficiency in material handling.

Gearboxes: In industrial gearboxes, cylindrical roller bearings are employed to support rotating gears. Their high load-carrying capacity and precision contribute to the reliable operation of gear systems.

Electric Motors: Cylindrical roller bearings are commonly used in electric motors, supporting shafts and reducing friction during the motor’s rotational motion.

Aerospace Engineering

Aircraft Engines: Precision is paramount in aerospace applications. Cylindrical roller bearings are utilized in aircraft engines, where their ability to handle high radial loads and maintain accuracy is crucial.

Control Surfaces: Components like control surfaces and actuators in aircraft rely on cylindrical roller bearings for smooth and precise movement.

Landing Gear Systems: The landing gear systems of aircraft utilize these bearings to withstand heavy loads during takeoff and landing.

Construction Machinery

Crane Systems: Cylindrical roller bearings contribute to the smooth operation of crane systems, supporting heavy loads and ensuring controlled movement.

Excavators and Loaders: In construction equipment like excavators and loaders, these bearings are employed in various components, including the boom and bucket mechanisms.

Concrete Mixers: Cylindrical roller bearings play a role in concrete mixers, ensuring the efficient rotation of mixing drums.

Railway Industry

Train Wheels and Axles: Cylindrical roller bearings are used in train wheels and axles, providing support for the heavy loads carried by trains. Their durability and load-carrying capacity make them suitable for railway applications.

Bogies: Components of railway bogies, including wheelsets and axles, incorporate cylindrical roller bearings for reliable performance and reduced friction.

Railway Motors: Electric motors in railway systems utilize these bearings to support shafts and ensure smooth operation.

What is a Cylindrical Roller Bearing Assembly

A cylindrical roller bearing assembly is a sophisticated mechanical component designed to facilitate smooth and controlled rotational motion in machinery. Let’s explore the intricacies of this assembly, breaking down its essential components and highlighting its critical role in various applications.

Components of a Cylindrical Roller Bearing Assembly

Inner and Outer Rings:

The assembly consists of two rings: the inner ring, mounted on the rotating shaft, and the outer ring, fixed within the housing. These rings provide structural support and define the bearing’s geometry.

Cylindrical Rollers:

The cylindrical rollers are the key elements responsible for carrying the load. These rollers are arranged between the inner and outer rings, ensuring even distribution of forces and minimizing friction during rotation.

Cage:

The cage, positioned between the rollers, serves a crucial role in maintaining proper spacing and alignment. It prevents direct contact between the rollers, reducing friction and wear. The cage design contributes to the overall durability of the bearing.

Functionality of the Cylindrical Roller Bearing Assembly

The assembly operates based on the principle of rolling motion, allowing for smooth rotation while supporting radial loads. Here’s an overview of how each component contributes to the functionality:

Inner and Outer Rings:

The inner ring supports the rotating shaft, while the outer ring is fixed in the housing. This configuration enables controlled rotation without compromising stability.

Cylindrical Rollers:

Cylindrical rollers distribute radial loads evenly across the bearing. Their cylindrical shape allows them to handle both radial and axial loads, making the assembly versatile in various applications.

Cage:

The cage ensures that the cylindrical rollers maintain proper spacing and alignment during rotation. By preventing direct contact between rollers, the cage minimizes friction, enhances efficiency, and extends the life of the assembly.

Advantages of Cylindrical Roller Bearings

High Load Capacity Discover how cylindrical roller bearings excel in handling heavy radial loads with ease.

Precision and Accuracy Delving into the precision engineering that ensures accurate positioning and reduced friction.

Versatility in Applications Exploring the diverse range of industries and applications where cylindrical roller bearings play a pivotal role.

FAQs

Are cylindrical roller bearings suitable for high-speed applications?

What maintenance is required for cylindrical roller bearings?

Can cylindrical roller bearings accommodate axial loads?

How do I choose the right size of a cylindrical roller bearing for my application?

Are there environmental considerations for cylindrical roller bearings?

Can cylindrical roller bearings be replaced individually, or should the entire set be changed?

Conclusion

In conclusion, understanding what is cylindrical roller bearing is crucial for anyone involved in machinery, from engineers to DIY enthusiasts. This guide has taken you through the intricacies, advantages, applications, challenges, and maintenance tips, providing a holistic view of cylindrical roller bearings.